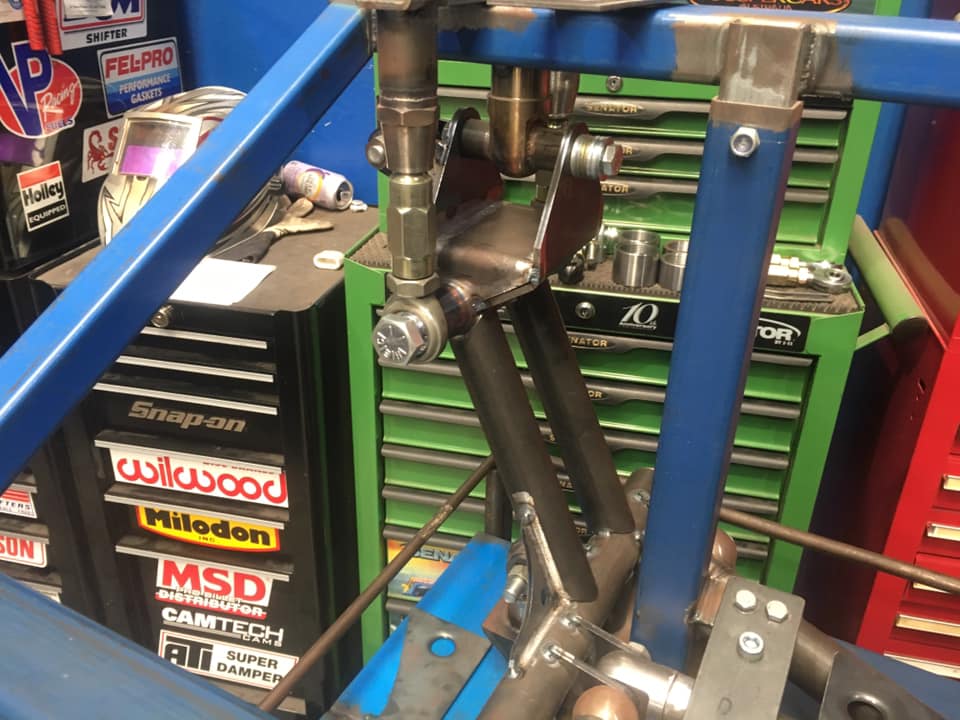

TC Cortina Subframe.

As part of our long relationship with one of the top fabrication shops in Australia, we were tasked with reverse engineering an innovative subframe assembly for the Ford TC Cortina with the intent to build assembly jigs, allowing accurate and repeatable manufacturing. This subframe uses Mustang 2 spindles which allow for multiple disc brake conversion options, offers coil over options and far greater tuning than the original suspension.

Client: Pro Street Metal Craft

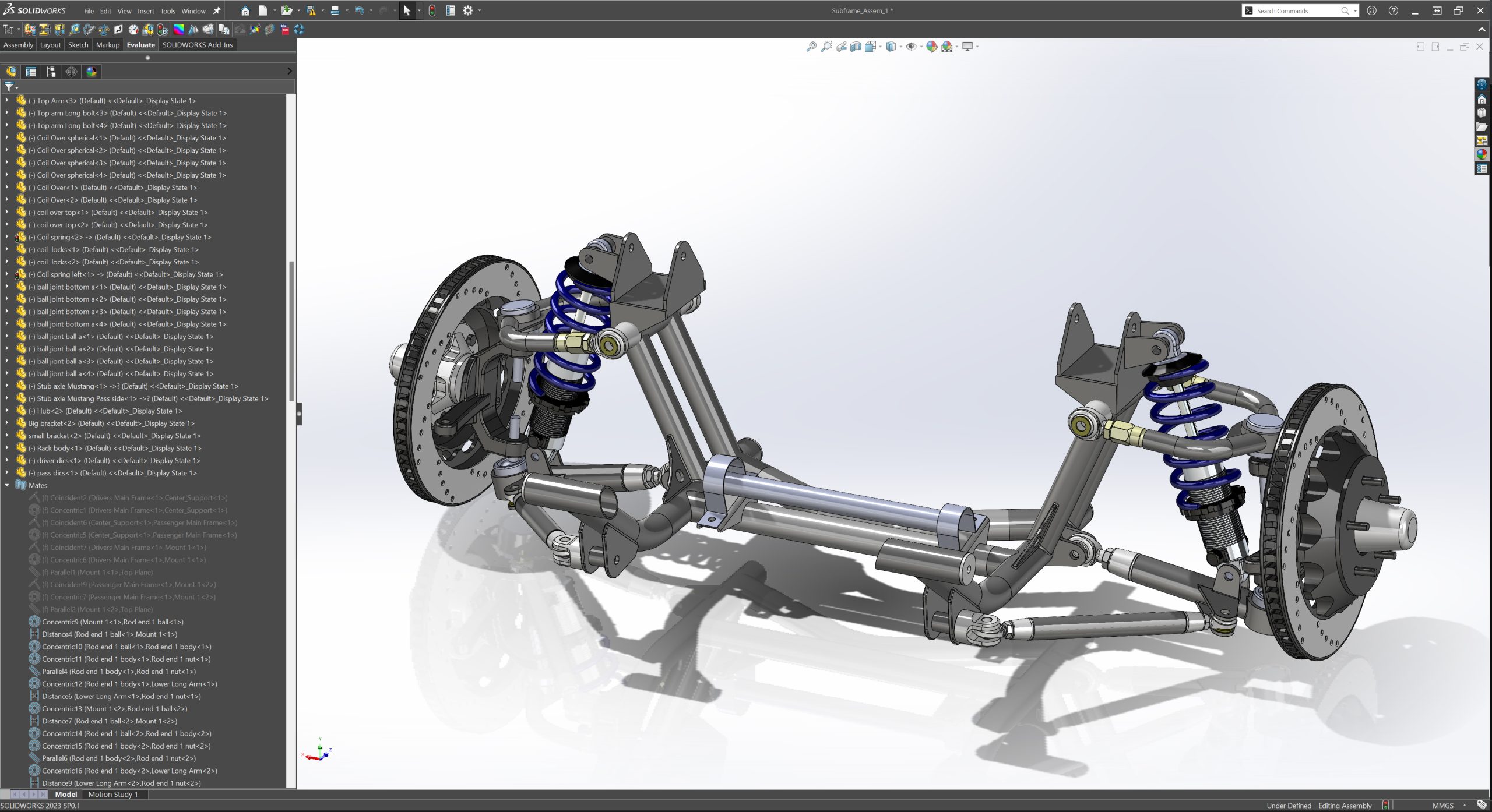

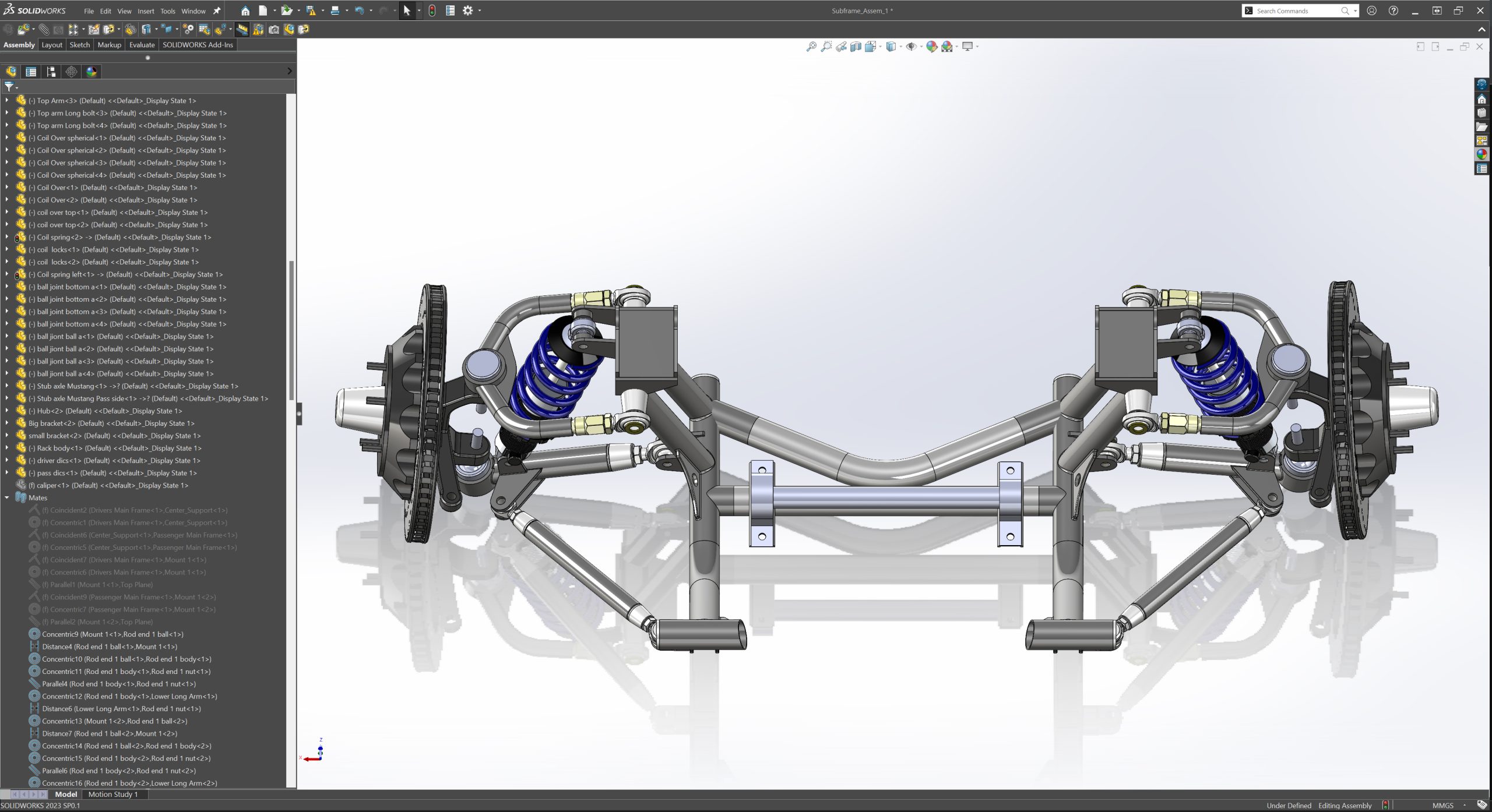

CAD Modelling.

Each part of the sub assembly was carefully measured and modelled in SolidWorks. A fully mated master assembly was built using these separate components, allowing to identify binding or interference of parts throughout the suspension travel.

Rendering.

Having the CAD assembly allowed us to generate photorealistic rendering for marketing purposes.

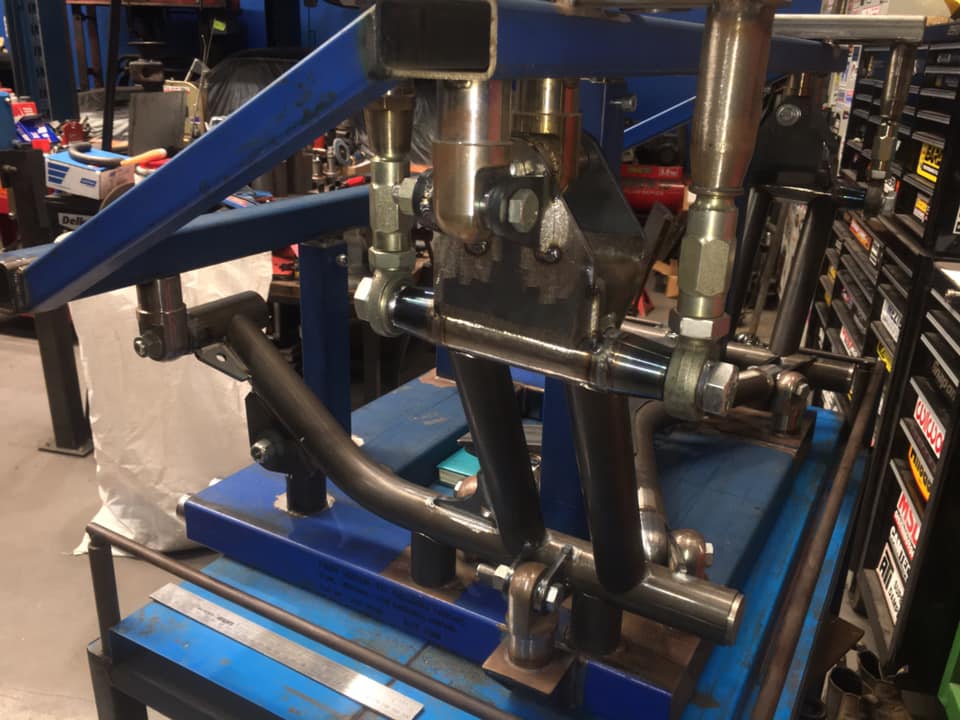

Jigs and Fixtures.

These were fabricated using key dimensional data generated by the CAD assembly. After several fine adjustments, production of the subframe commenced.